How Do You Decide Which Weld Joint to Use

Plasma Cutters for Metal Fab. For the frame I used 2 x 3 tubing because it is very sturdy and easy to weld but you could also use angle iron or C channel.

How To Weld Five Basic Welding Joints Welding Diy Welding Metal Workshop

You can use an angle grinder or sandblasting.

. Or you can use non-chlorinated degreasers to remove the oil. This results in more weld metal going into the joint which can increase productivity in the welding operation. 160103 under United States federal regulations without entering into a separate business associate agreement with NEOGOV that permits you to do so.

Using AISC Table J25 indicates that you need to check the shear capacity of the base metal for shear as part of the weld design. But if it is placed above the line then it is supposed to go on the opposite side of the joint. Welds are typically quality tested based on the function for which is intended and under conditions that are the same or more severe than those encountered by the welded structures in the field.

You will need a large Phillips head screwdriver 10mm wrench and they say a 16mm wrench which I didnt have in my wrench set but I used a 58 wrench successfully instead. You can also use CG-12 which is the cast equivalent to using a 309. Depending on the liquid you are using you can apply heat to the soldering joint in a circular motion.

Finally use a file to remove any remaining carbon or abrasive material. Manufacturers recommend a special type of PVC cement that has a longer open time than the type of cement that plumbers use on plastic pipes. For example you may not use the Services to collect protect or otherwise handle protected health information as defined in 45 CFR.

One advantage of PVC is that you can weld joints to keep them tight and prevent water from penetrating behind the trim. If you need under 3000 parts rotomolding can suite your needs. I thought the instructions were very well written easy to follow and clear.

You might also want to get a few pieces of scrap metal that you can use as a butt joint. Clean at least 1 25 cm next to the joint to bright metal. The best way to decide whether or not rotational molding will work for your project is to look at your annual production volume.

What Welding Rod Do I Use to Weld Stainless to Carbon Steel. At that point however its unlikely that the weld strength will be the limit state that fails. Since stick welding requires a lot of skills and the learning curve is different you should also do a practice run before you start.

When the metal piece achieves a glowing sully cherry red look you can focus the heat on the solder joint. However due to its capacity limitations and the cost of refurbishing and rebuilding the tooling it becomes cost-restrictive once you breach that. I included photos of the instructions so you can decide for yourself.

And receive 1000 free brokerage when you use promo code FND1000. The benefit of using 309L is that it contains no molybdenum. The ability to reduce spatter distortion and burn-through also helps improve productivity since less time will.

If the cast iron component has absorbed oil you can use a flame torch and preheat it to burn the oil. If youre having a hard time deciding keep in mind that the easiest way to remember the difference between a spot tack weld is that the tack weld is an initial step for positioning and securing items for welding while the spot weld is the permanent and final join mostly used for. It is recommended to use a 309L when you are joining stainless steel with a more milk steel which includes carbon steel.

Sometimes you need to cut metal before you can join it together. There are many Eastwood welder reviews from real customers to help you decide which one is right for you. Lay a weld on a piece of scrap metal before you actually do a.

Are excessive post-weld grinding and cleanup costing too much time and money. Multi-process welders let you easily switch modes depending on the type of weld and the material youre working with. Use these questions to help you decide.

The Orientation of the Weld. When you see that the type of weld is placed below the reference line it means that the weld should be on the same side of the joint as the arrow side. The company holds an interest in the Mount Weld project Western Australia.

If you want to build your own trailer you can buy trailer kits online that include the axle wheels springs hitch and lights so all youve got to do is weld up a frame. You can use the same techniques which you could use for solder wires or strip. To really test a weld you need to do a x-ray test magnaflux test dye penetrant test or ultrasonic test which looks for voids lack of fusion etc.

You can buy this cement wherever you buy the trim. You could use a 25mm weld on a 19mm plate in a t-joint.

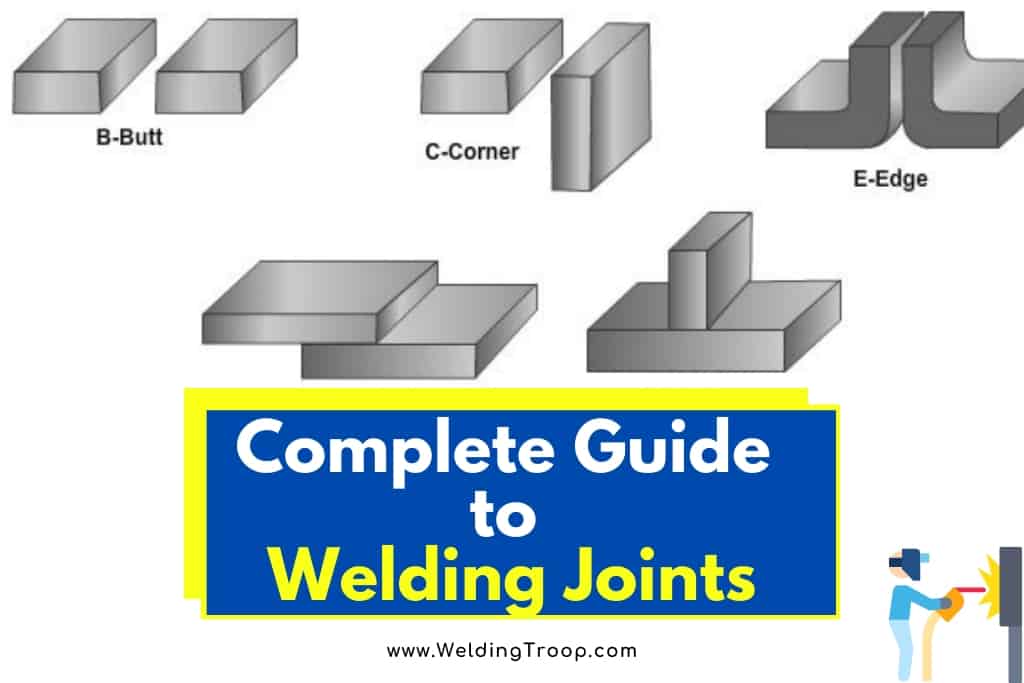

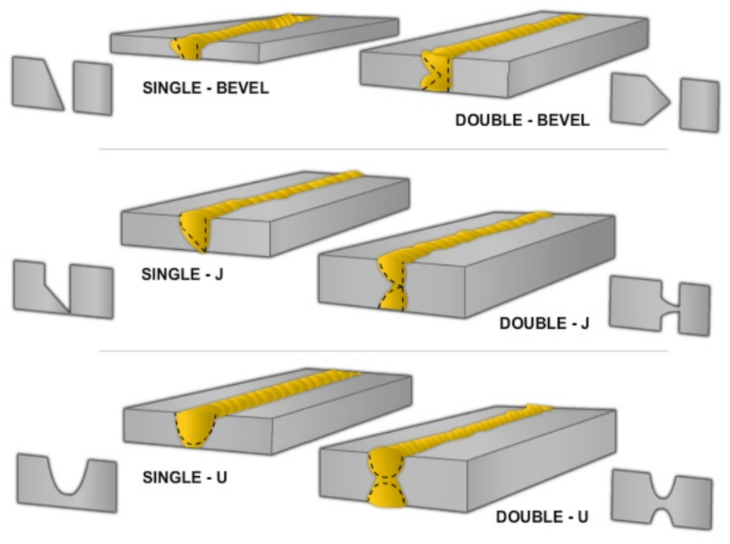

Welding Joint Types Butt Joints Lap Joints Tee Joints More

Welding Joint Types Butt Joints Lap Joints Tee Joints More

Welding Electrode Numbers Mean Google Search Welding Welding Projects Welding Rods

When Choosing A Process And Filler Metal For Welding Stainless Steel Fabricators Need To Consider T Welding Shielded Metal Arc Welding Stainless Steel Welding

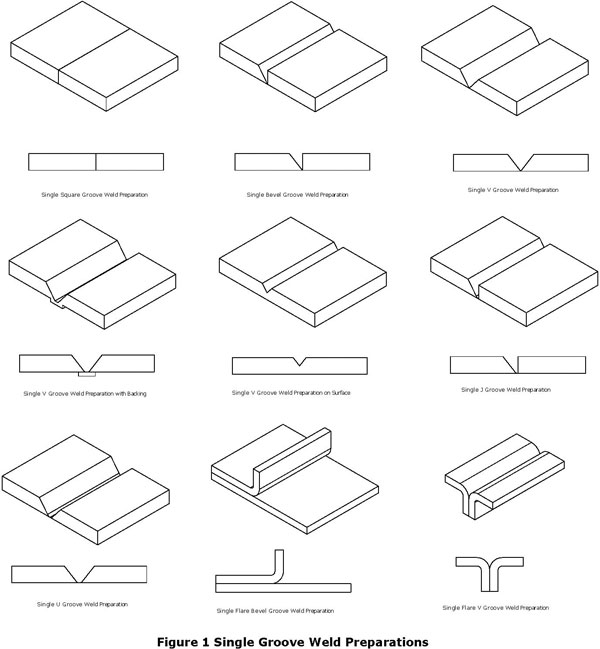

Understanding Weld Symbols The Groove Weld Meyer Tool Mfg

Welding Processes Welding Table Welding Projects Welding Process

Techniques For The Overhead Arc Welding Position For All You Stick Welders Out There Welding Projects Welding Arc Welding

Image Result For Welding Symbols Welding Symbols Welding Tips

Welding Joint Types Butt Joints Lap Joints Tee Joints More

Welding Symbols Karthik Kumarasamy Welding Welding And Fabrication Welding Crafts

Guide To Welding Joint Types And Parts Welditu

Different Types Of Welding Rods Explained Welding Rods Welding Types Of Welding

Magnificent Sorted Diy Welding Projects You Could Look Here Welding Projects Welding Training Welding

Arc Welding Basics Welding Projects Arc Welding Welding And Fabrication

Discovering The 7018 6013 6011 And 6010 Welding Rod Sizes Chart Welding Rods Smaw Welding Rod

5 Types Of Welding Joints And Their Use Complete Guide

The Ultimate Guide To Smaw Stick Welding Welding Projects Smaw Welding Welding Rods

Comments

Post a Comment